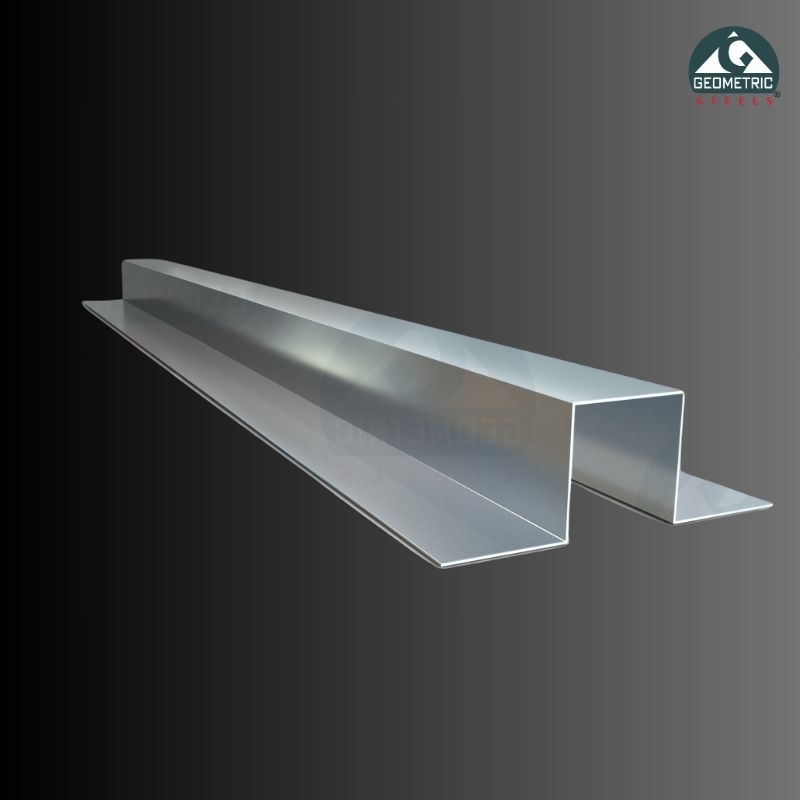

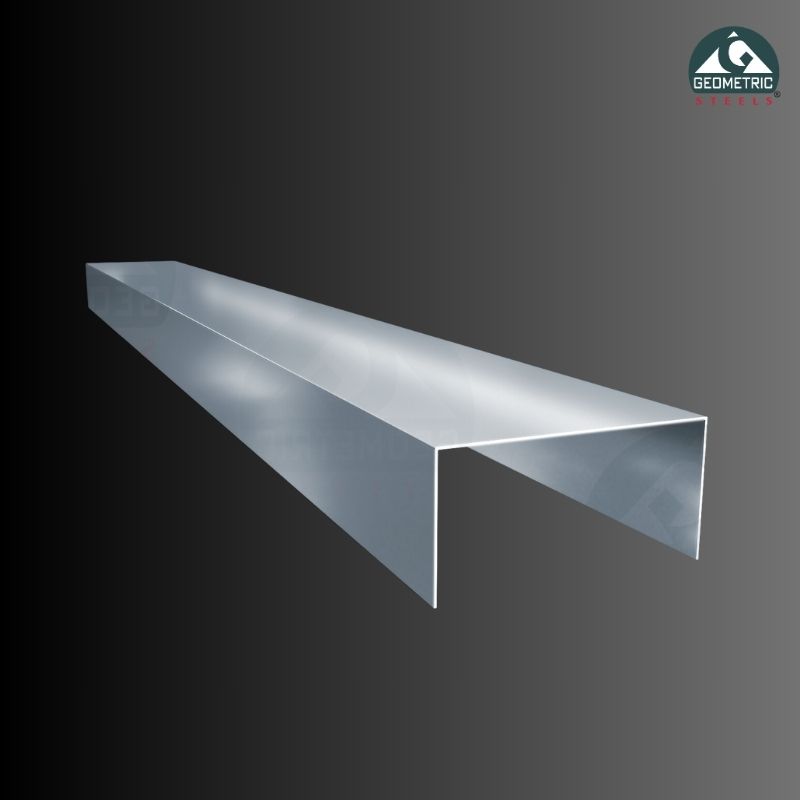

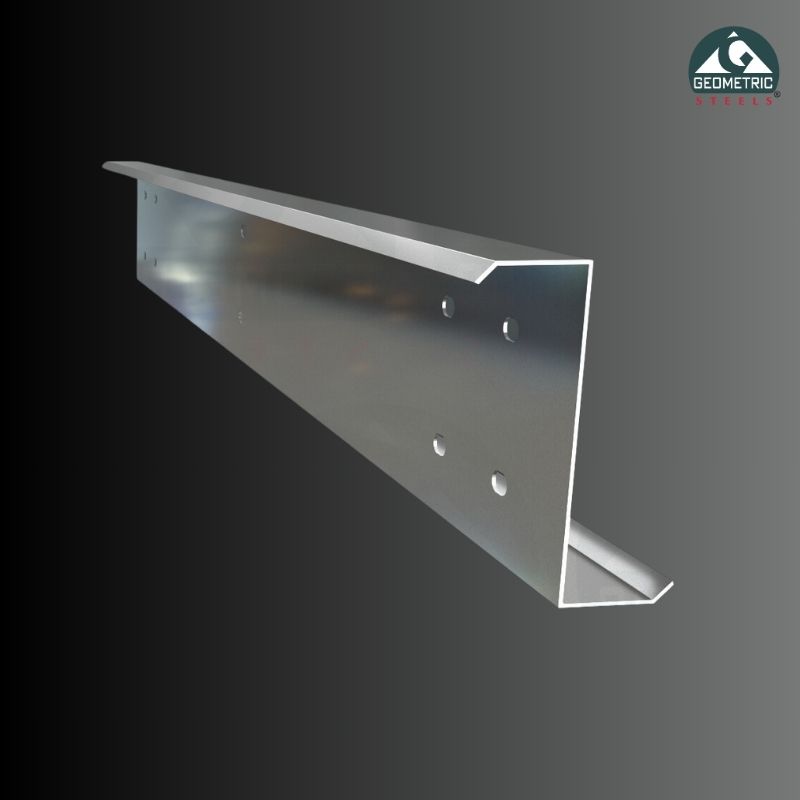

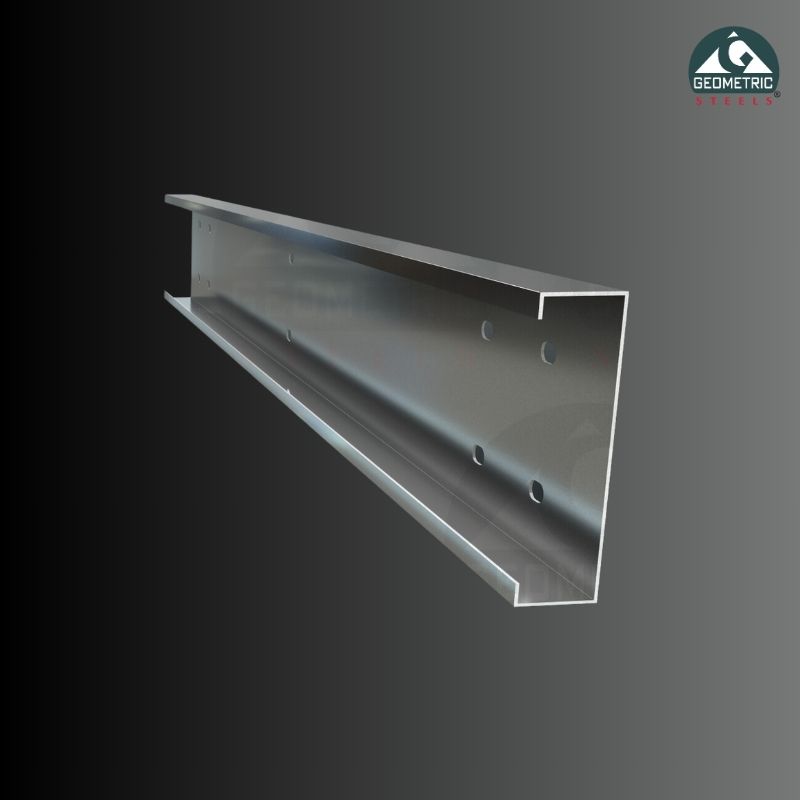

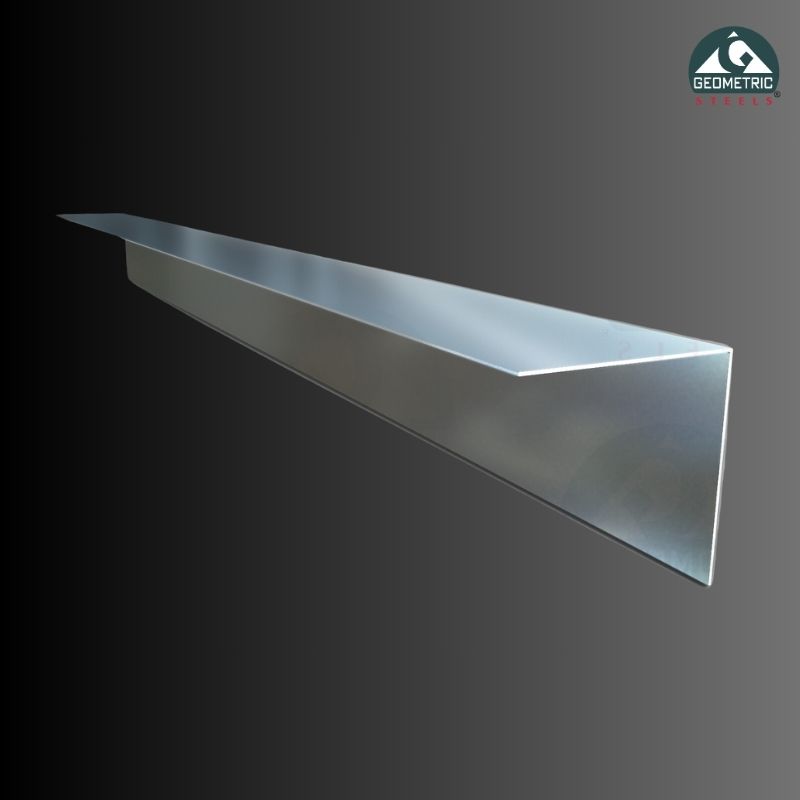

Hat section purlin consists of two outward flanges and two vertical sides of the hat. Geometric Steel manufactures top hats for a variety of residential, commercial, and industrial purposes. Manufactured from high tensile galvanised steel (240Mpa and 350Mpa), Galvalume G550, AZ150, and CR in standard lengths up to 6.1 metres, with rib stiffener option.