Metal Louvers

These vertical louvers are placed to offer sight-proof screening, prohibiting visibility through them. These louvers are designed to be very water resistant, effectively blocking water entry. They are an essential component of air handling devices and are used in dusty environments such as swimming pools, restaurant lounge railings, and open kitchens. Typically installed as the first unit at the point of air intake, they capture bigger dust and sand particles, preventing them from flowing through.

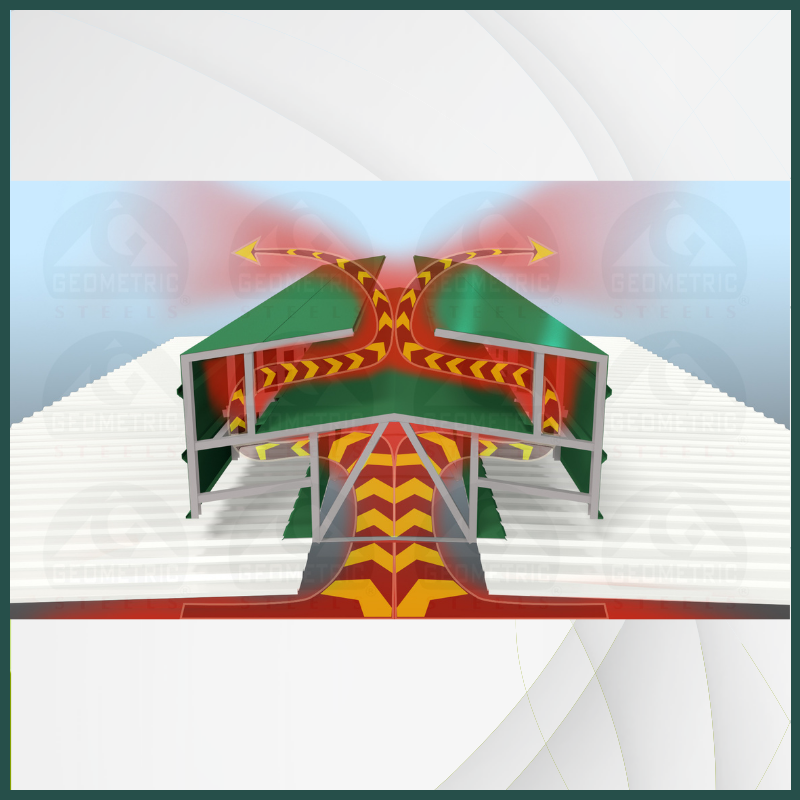

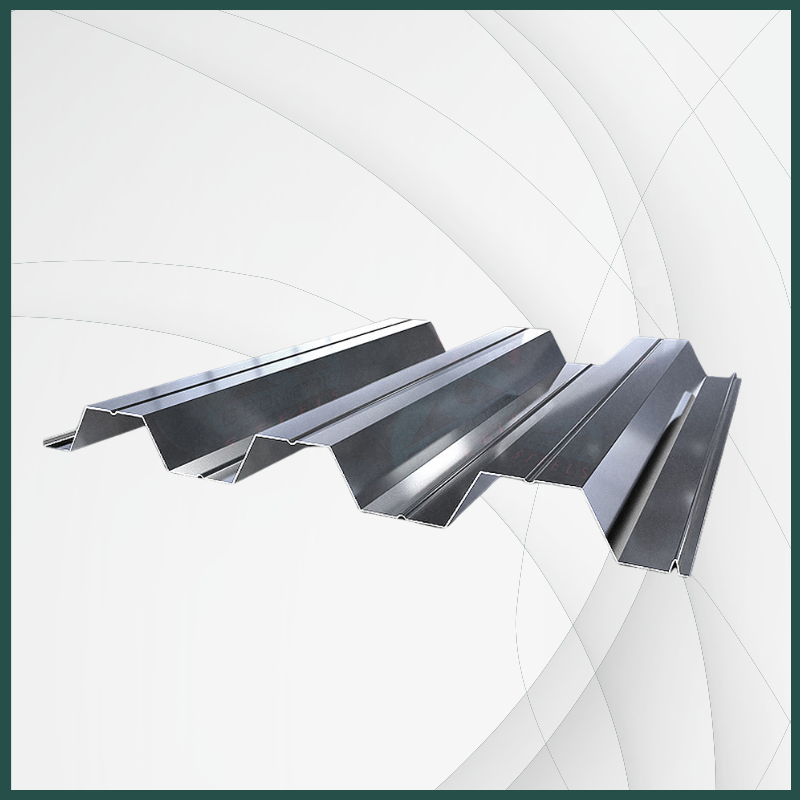

Sand Trap Lovers are also used for ventilation in parking lots, warehouses, generator rooms, fan rooms, swimming pools, restaurant lounge gates, open kitchens, and other arid or sandy environments. Geometric Steels designed sand trap louvers with a series of U channels on one side and a parallel set of inverted U channels with the Self Emptying System. It features a bottom face aperture in the casing for releasing separated sand particles. This configuration generates a resistance or barrier for sand particles in the intake air, causing them to settle. Sand poured through the drain opening and the Geometric steel's unique pattern. The Sand Trap Louver makes it self-cleaning.

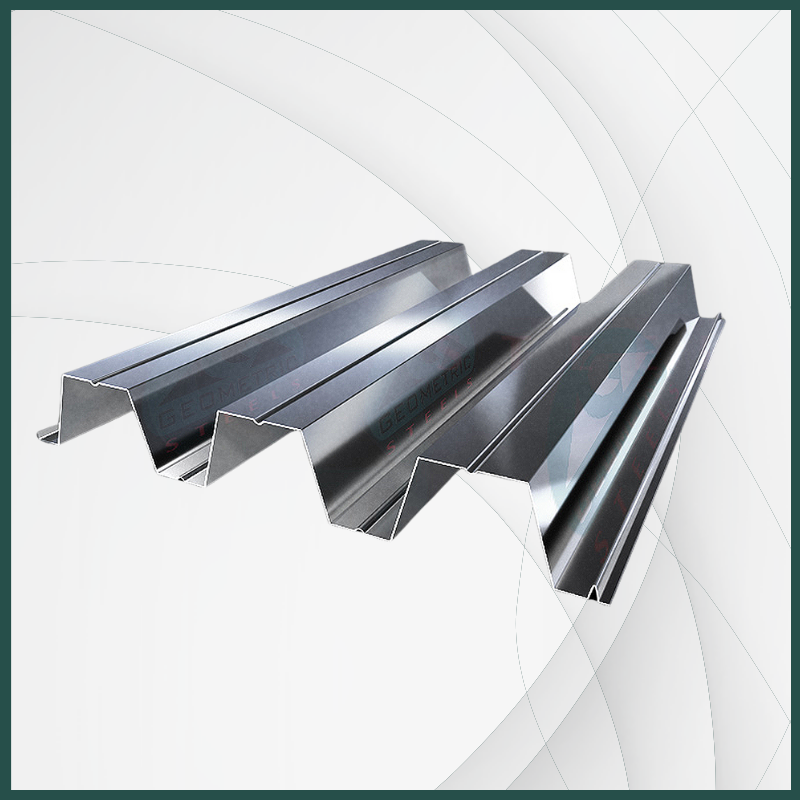

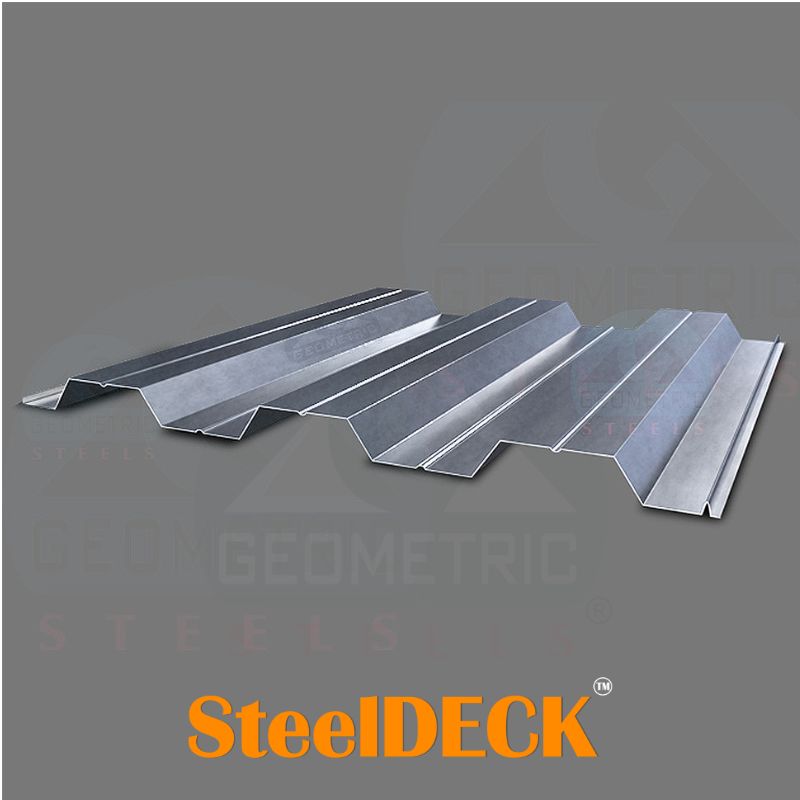

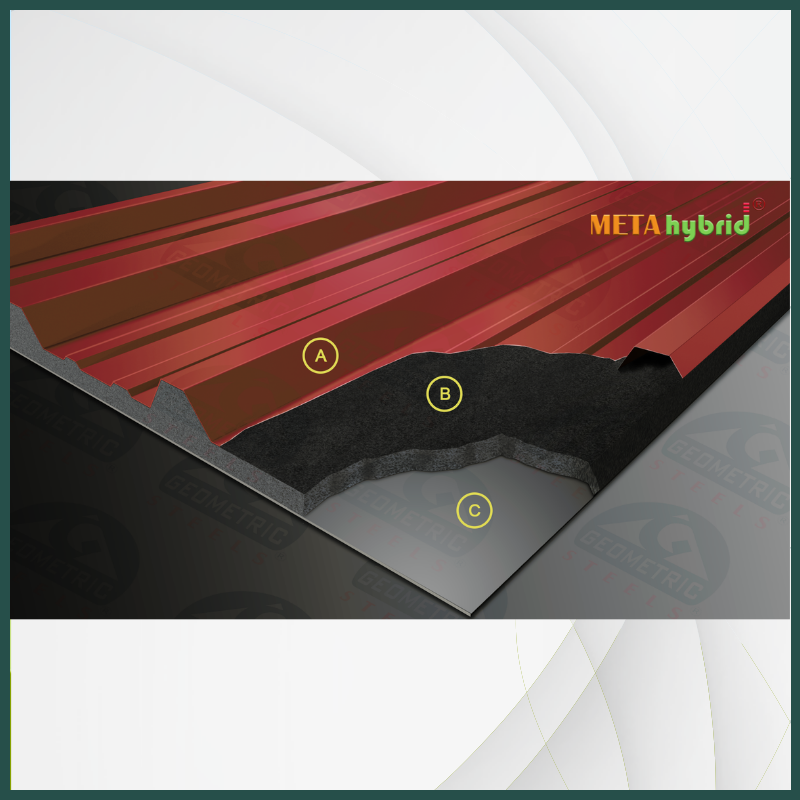

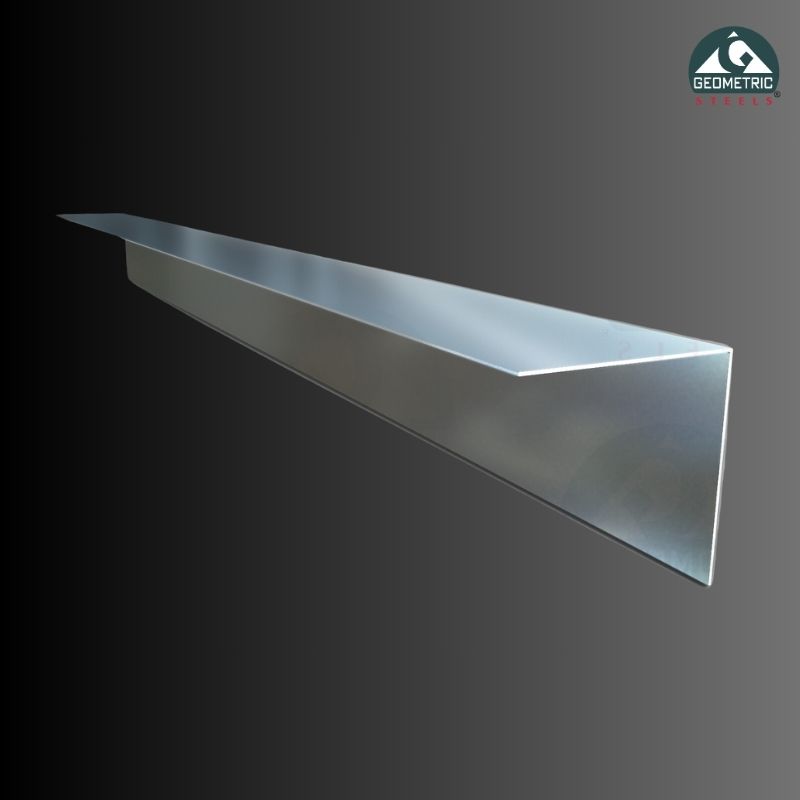

• The frame and blades are made of high-quality color-coated steel, extruded aluminium, stainless steel, and powder-coated aluminium profiles, which provide corrosion resistance and rigidity.

• Two sets of inverted U-channels were installed vertically on opposite rows.

• The Geometric steel's unusual design has an open bottom compartment for emptying filtered sand and dust.

• G.I. color-coated, aluminium, powder-coated, or stainless steel are all available options.

• Geometric steels are unique in their ability to segregate sand and dust from the air stream.

• Typically used in ventilation applications and at the inlet duct of an air handling device.

• Bird screen to defend against the intrusion of big objects.

Standard Construction

• Material: Galvanise colour coated /Aluminum powder coated/ Stainless Steel

• Finish: Colour coated / powder coated /Mill

• The minimum size is 300 mm H × 300 mm W,

• maximum size is 3050 mm H x 4500 mm W in aluminium powder coating.

• Maximum Dimensions: 5000 mm H x 5000 mm W in Galvanise colour coated

Water penetration for louvers refers to their ability to resist water entry under wet weather. Louvers, which are commonly seen in ventilation or shade systems, combine airflow with rain protection. Lower penetration rates indicate effective water penetration resistance in geometric steel louvers, which prevents building water intrusion. Design parameters like as blade direction, spacing, and drainage have an impact on louver system water penetration performance.

Optional (additional cost)

• A variant of bird or insect mesh

• Mounting Clips and flanged frame

• Heavier thickness blade or frame construction

Send Message