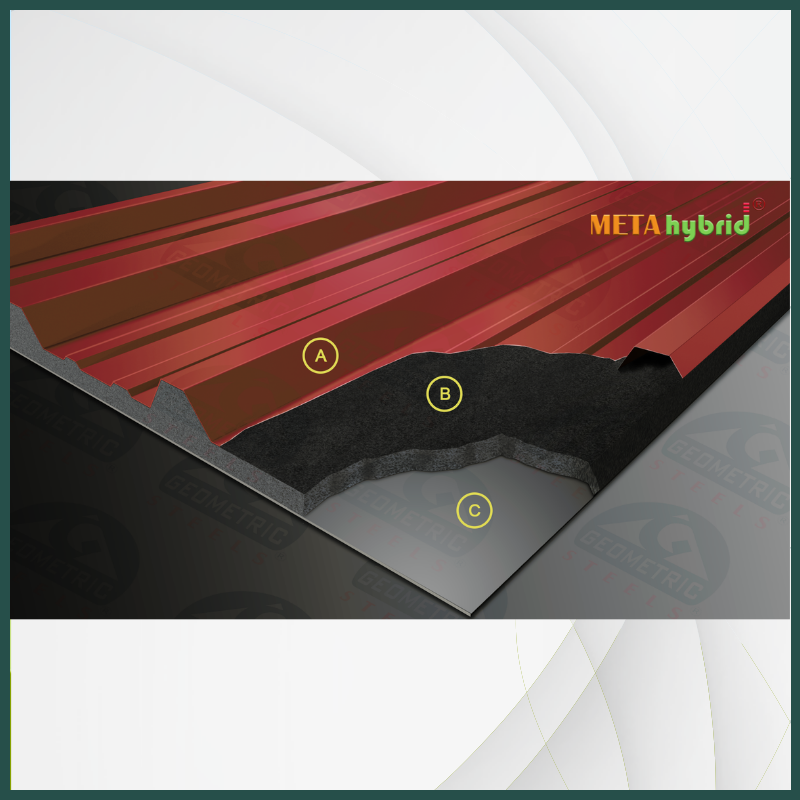

Thermal Insulated Roofing Sheets

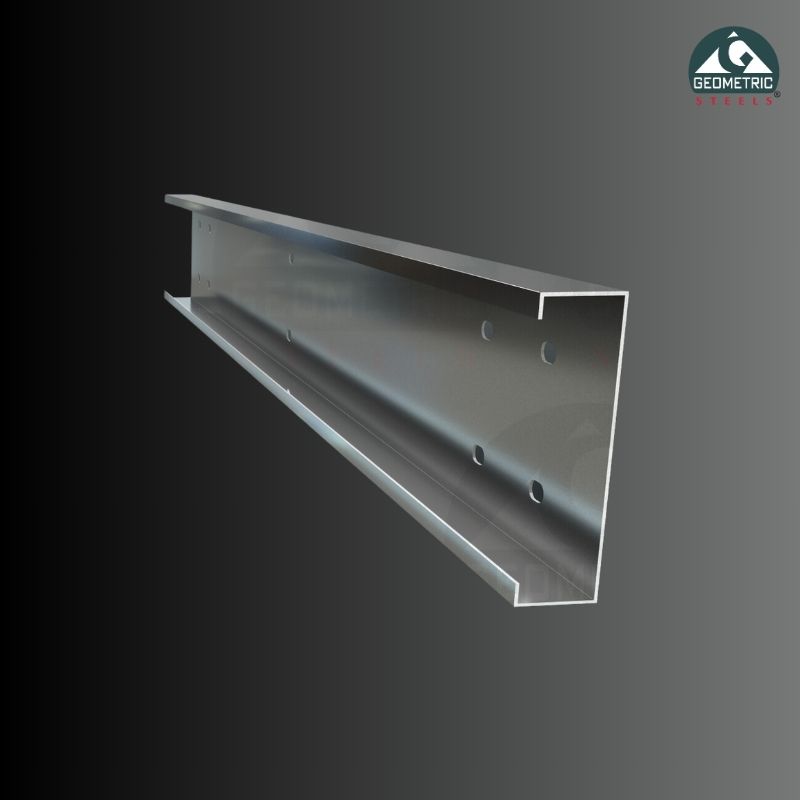

A: The top surface layer is a metal profile sheet that contributes to steel's strength and durability. Available in PPGI/GL/PPGL/AL profiles with 1135mm real and 1060mm cover widths.

B: Intermediate Layer: It is a specific insulation material that can be 19 mm, 24 mm, 30 mm, or 50 mm thick, depending on the purpose.

C: The bottom lying layer is a metal sheet that provides strength and durability for steel, available in PPGI/GL/PPGL/AL.

Thermal Insulated Double Skin Roofing Sheets

It is critical that each structure has adequate thermal insulation that is appropriate for its intended use. The system includes composite double skin roof panels and a pre-assembled insulated roof sheet. They are sandwich-style, with insulating filler between two metal layers: a steel-profiled top sheet and plain steel at the bottom.

Composite double skin panels come pre-assembled, making installation much easier on-site. The insulation minimises noise and radiant heat; it functions as a circuit breaker, making it ideal for working inside; it is low maintenance and highly rated for thermal performance; and it is a great way to insulate the roof and cladding of any building.

omposite panels reduce radiant heat through roofs and walls, keeping your building cool while also lowering your carbon footprint and saving money on ever-increasing energy costs. Solar panel installation is also possible on thermally insulated roof sheets because of their profile benefit.

THERMAL-INSULATED METAL ROOFING SHEETS

Profile: You can mix-and-match different manufacturers' double skin composite composed of steel, which has the strength and strength of steel Colour Coated Galvanise, Colour Coated Galvalume, and bare Galvalume with the option of our regular colours. 0.50mm thickness. It also comes with off-white simple liner panels that face the building. The inside seems clean and aesthetically nice. Twin skin metal roofs are quick and easy to install, and they combine great performance with variability in insulation thickness based on building utility requirements. A sealed, watertight construction provides total weatherproofing.

Width and length: The top sheet measures 0.50mm actual 1135mm with a coverage width of 1060mm spread profile (composed of four valleys and three profiles). The panels are simply lapped and have a cover width of 1060mm when mounted with reduced lap loss and increased cover width. We construct panels to the customer's exact requirements from 600mm to 6000mm in length.

Double skin insulation thicknesses include 12mm, 19mm, 24mm, 30mm, and 50mm.

Roof lights: Factory-profiled polycarbonate roof lights are used in conjunction with a Thermal Insulated Sheet, which is brought to the job site ready for easy and quick installation.

APPLICATION

• Warehouse / Cold Storage

• Fruit Ripening Chamber Shed

• Site Office Building

• Chemical Industries

• Food Industry

• Factory Building

Send Message