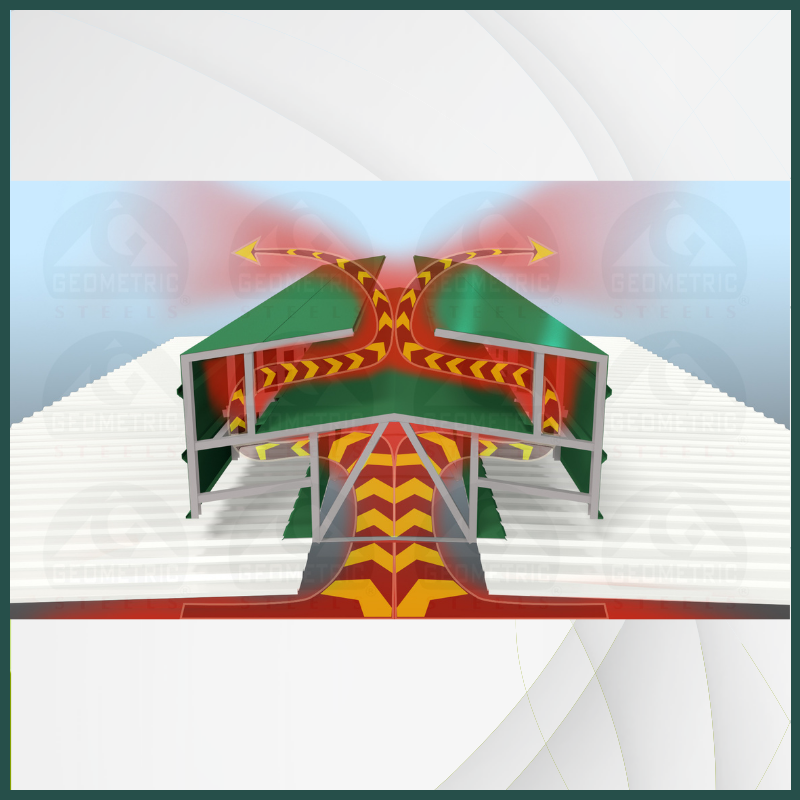

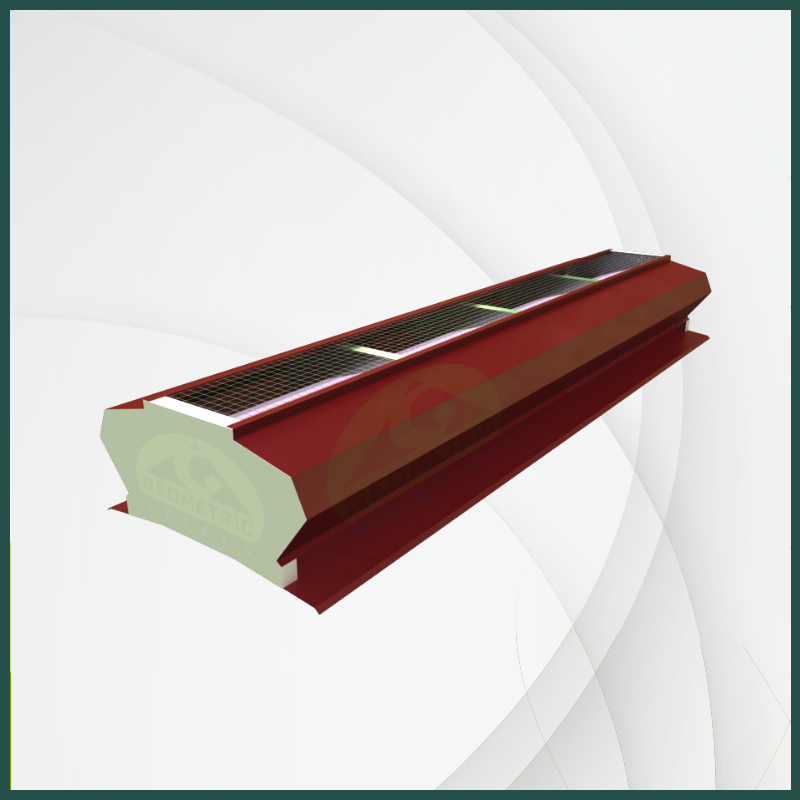

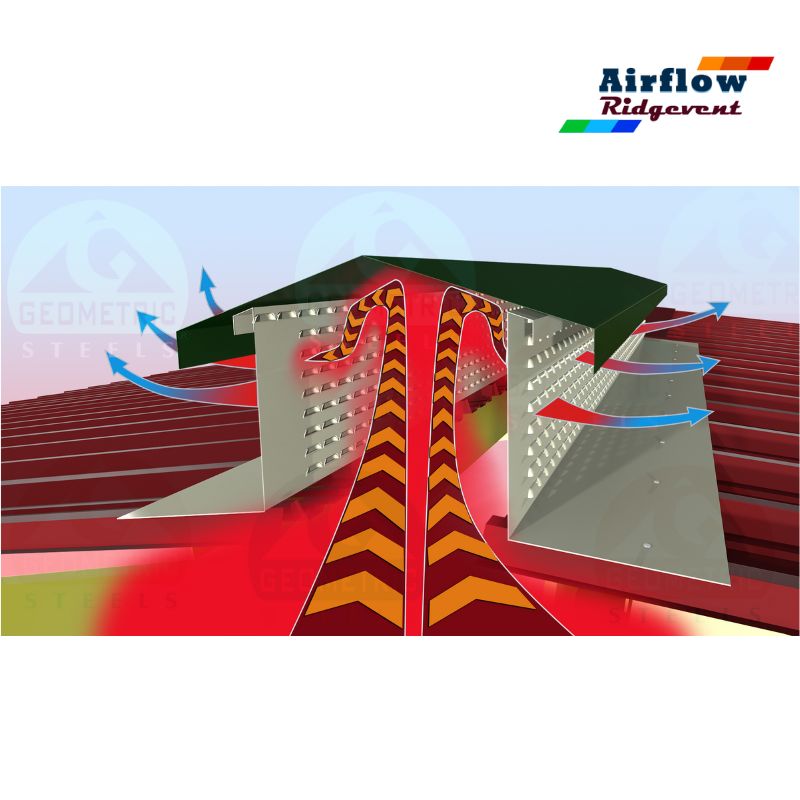

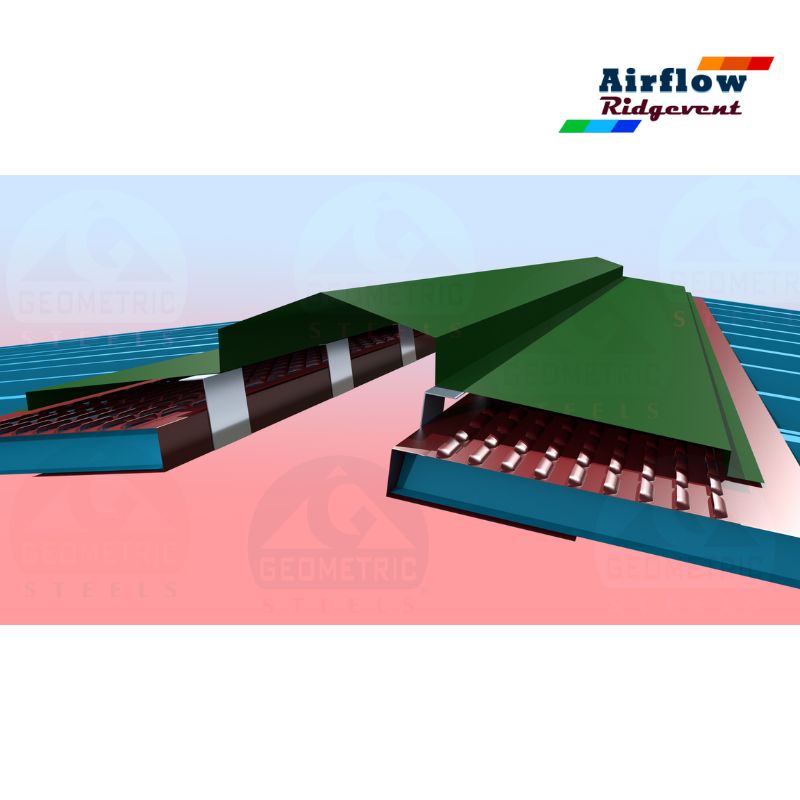

Apex vents are organised on-site. Constructed roof vents are roofing components that are custom-designed and installed directly on the roof's ridge to promote airflow in factories. The procedure of manufacturing frames at our plant and then installing them on-site vents on the ridge requires the material to meet the roof's ridge standards. The ridge vent is installed along the whole length of the roof ridge, allowing hot air to depart the factory's building space while fresh air enters through the inlet or opening vent. Apex-type airflow. Ridgevents are constructed on-site and have several advantages. Because they are designed to fit perfectly on the roof, they provide better sealing and are less likely to leak. Apex Ridgevent consists of two frame buildings. It is simple to deliver and setup. In our plant, the primary and secondary structures are welded. They are stable and firm. Based steel is welded to the main frame structure near the ridgevent throat. to allow it to be a portion of the roof. The sideboard uses an edge-flashing profile sheet that has been pressed and coloured. The ridge can be utilised with transparent polycarbonate sheets or metal sheets with colour coating. A flow guide plate with a leak-proof solution allows rainwater to flow onto the roof. The ventilation system Apex Ridgevent was created especially for roofs. consisting of both primary and secondary frameworks Convenience is the focus of both the installation and construction processes.

Send Message